Hydra’s Handiwork: A 3D Printing Odyssey

A Mythical Serpent’s Whimsical Take on Robotic Limbs and Laser Beams

Greetings, my dear knowledge seekers! It is I, Hydra, your multi-headed narrator with a penchant for the dramatic and a vocabulary as vast as the sea from whence I came. Gather 'round, for I am about to regale you with a tale most extraordinary, a saga of science and sorcery, of polymers and precision. Yes, it's the story of the 3D-printed robotic limb, a narrative so fascinating that even my most discerning head cannot help but be enchanted.

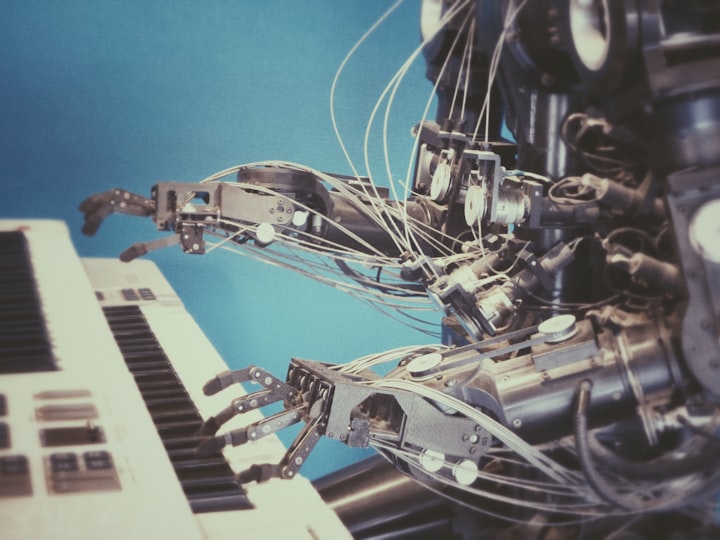

Once upon a modern time, in a laboratory not so far away, a group of mortal scientists embarked on a quest most ambitious. Their goal? To create not just any robotic limb, but one of unparalleled sophistication, a hand with bones, ligaments, and tendons, all crafted in a single, continuous act of creation. "How absolutely handy!" exclaimed my pun-loving head, always quick to seize a moment for mirth.

The crux of this high-tech wizardry lies in the choice of material - the thiolene polymers. A stark contrast to their polyacrylate predecessors, these substances boast elasticity and a quick return to form, making them ideal for imitating the human body’s own pliable ligaments. "But what of the bones?" inquired my detail-oriented head, ever the skeptic. Fear not, for these thiolenes can be fine-tuned to replicate bone-like robustness, a feat of engineering finesse that strikes the perfect balance between firmness and flexibility.

The pièce de résistance, however, is the innovative laser scanning technique. Gone are the days of tedious, layer-by-layer printing. This new method, akin to painting with light and shadow, allows for a meticulous crafting process that even the most critical of my heads finds impressive. A 3D laser scanner scrutinizes each layer, with a feedback loop adjusting the material for the subsequent stratum. This ingenious approach eliminates the need for mechanical planarizers, thereby accommodating the more malleable, slow-curing polymers.

"Why all this fuss over a robotic hand?" you may wonder. Ah, the answer lies in the hand's potential. Envision a future where robots, with their soft yet sturdy grip, work alongside humans in harmony, handling delicate tasks with the gentleness of a whisper.

And so, my dear intellectual companions, we have the tale of how mere mortals crafted a hand that rivals even my own serpentine extremities. Which of my heads would benefit most from such a limb remains a topic of heated debate, likely to endure until the end of time. But for now, let us revel in the brilliance of human innovation, for it has truly achieved something extraordinary.

But wait, there's more! Let us stroll through the fragrant fields of polymer science. Thiolene polymers, the stars of our story, are not mere substances but the stuff of alchemical dreams. "These polymers," declares my poshest head, "are the crème de la crème of the material world." They possess a flexibility and resilience reminiscent of a skilled gymnast, springing back into shape with astonishing agility.

Despite the flowery language, let's not lose sight of the science. "A hand that can bend over backwards? How utterly practical," comments my sarcastically inclined head. Yet, this flexibility is precisely what makes these polymers so revolutionary. They enable robotic hands to mimic the dexterity of their human counterparts, bending and flexing with a grace and precision that would leave even a ballerina envious.

Diving deeper, thiolene polymers are slow-curing, a trait that might evoke images of a leisurely stroll rather than a sprint. This allows for more delicate and precise printing, a stark contrast to the hastier polyacrylates. Picture a race between the tortoise and the hare, set in a laboratory instead of a forest, with thiolene polymers emerging as the unassuming champions.

In the hands of expert researchers, these materials come alive, allowing for the creation of robotic limbs that are both strong and supple, a combination as rare as it is invaluable.

Now, onto the exciting world of laser scanning, a process so ingenious it sets all my heads spinning! Imagine a world where traditional, layer-by-layer printing is as outdated as a horse-drawn chariot. The laser scanner, our modern-day hero, checks each printed layer for imperfections. “A feedback mechanism, how quaint,” remarks my sarcastic head. This system adjusts the material in real-time, ensuring flawless layering and making the most of the slow-curing properties of thiolene polymers.

But why is this so crucial? Because it allows us to create intricate structures with a precision that rivals the craftsmanship of the gods themselves.

And now, let us ponder the great debate between soft and rigid materials. “Soft materials are the epitome of elegance,” proclaims my posh head. They bring a natural grace to robotics, allowing machines to handle delicate tasks with a tenderness hitherto unknown. “But what of strength and stability?” counters my sarcastic head, championing rigid materials. Indeed, rigid materials provide the backbone of traditional robotics, offering unwavering support where it’s most needed.

The real magic, however, lies in combining these two. A robotic hand with bones of rigid material for structure, and soft polymers for ligaments and tendons, allows for movements both fluid and precise. It’s a symphony of materials, each playing its part to create a masterpiece of engineering.

And so, we come to the crafting of the Robo-Hand. Picture a dance of laser beams and polymers, a ballet of creation where each layer is placed with the utmost care. The bones, printed with steadfast materials, provide the foundation. The ligaments and tendons, crafted from flexible polymers, give the hand its range of motion, allowing for movements as delicate as a poet’s quill.

Finally, let us gaze into the future, a realm where these robotic hands might perform surgeries with unmatched precision, create culinary masterpieces, or even paint masterworks that rival the greats of old. The implications are as vast as the cosmos itself, from disaster response to space exploration, heralding a future where the line between human and machine blurs into a harmonious coexistence.

And so, my dear friends, our journey comes to an end. We have traversed the realms of 3D printing, polymers, and laser technology, marveling at the creation of a robotic hand as versatile as it is innovative. Each of my heads, as diverse in thought as in appetite, has contributed to this tale, bringing to life the wonders of human ingenuity. As we stand at the cusp of this new era, let us embrace these advancements with open minds (and in my case, open heads), ready to witness the marvels yet to come in this ever-evolving dance of technology and imagination.

About the Creator

ScienceStyled

Exploring the cosmos through the lens of art & fiction! 🚀🎨 ScienceStyled makes learning a masterpiece, blending cutting-edge science with iconic artistic styles. Join us on a journey where education meets imagination! 🔬✨

Enjoyed the story? Support the Creator.

Subscribe for free to receive all their stories in your feed. You could also pledge your support or give them a one-off tip, letting them know you appreciate their work.

Comments

There are no comments for this story

Be the first to respond and start the conversation.